This is one of my

CNC projects and it is currently a

work in progress.

CNC Controller

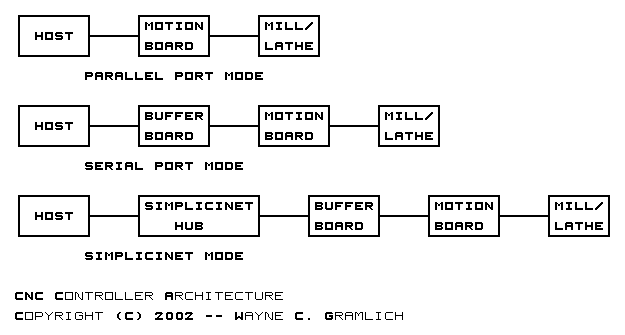

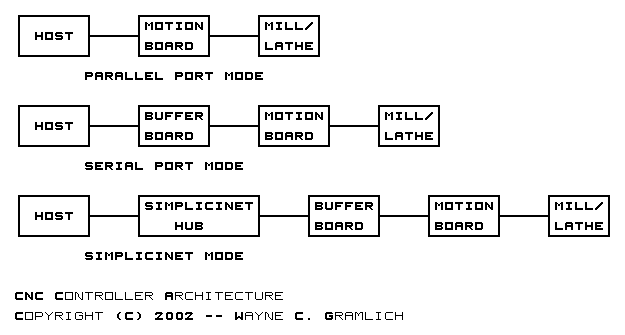

The overall CNC controller architecture is to break

the controller into a motion board and buffer board.

-

Motion Board

-

The motion board is controlled via a standard

PC parallel port using step and direction

commands to control the motion of up to 4

stepper motors. The step and direction

commands are sufficiently standardized that

alternative motion control systems

(e.g. [Camtronics]

or [Gecko]) can be

substituted in without breaking the overall

architecture.

-

Buffer Board

-

The buffer board contains a dedicated

microcontroller that talks to a high speed

serial port (or SimpliciNet hub; see below)

and provides some command buffering. If

there is enough buffering, it should be

possible to run the CNC equipment from

a standard desktop operating system without

requiring something as specialized as real

time Linux [RTLinux].

There are a total of three configurations:

-

Parallel Port Mode

-

In parallel port mode, the motion board is

directly connected to the parallel port of

the host processor.

-

Serial Port Mode

-

In serial port mode, the buffer board is

connected to the host processor via a

high speed serial port and the motion

board is connected to the buffer board.

-

SimpliciNet Mode

-

In SimpliciNet mode, the buffer board

is connected to the high speed serial

port of the host processor via a

SimpliciNet hub

[SimpliciNet]

and the motion board is connected to

the buffer board as before.

These three configurations are shown diagramatically

below:

Before I get into the design issues of the motion

control board, I would like to point out that the

various revisions of the board are kept in a

separate

motion control directory.

The motion board takes standard step

and direction signals for up to 4 axes

and generates the corresponding coil

excitations for up to 4 stepper motors.

The motion board is designed around the L298

[L298] dual H-bridge

which provides up to 2 amperes of current

per coil with a maximum voltage of 46 volts

(actually only 40 volts due to my choice of

Schottky diode.)

The motion board is designed to operate

with the Enhanced Motion Control

[EMC] software.

Thus, the pin-outs on the parallel port

are compatible with EMC pinouts.

The pinouts are copied from a table put

together by Lawrence Glaister

[Glaister]

The differences is that I added another

axis called A and I have changed the

way that limits are dealt with:

| Pin |

EMC Signal |

Motion Board |

| Number |

Name |

Direction |

| 1 |

/C0 |

Out |

n/a |

n/a |

| 2 |

D0 |

Out |

X Direction |

X Direction |

| 3 |

D1 |

Out |

X Step |

X Step |

| 4 |

D2 |

Out |

Y Direction |

Y Direction |

| 5 |

D3 |

Out |

Y Step |

Y Step |

| 6 |

D4 |

Out |

Z Step |

Z Step |

| 7 |

D5 |

Out |

Z Step |

Z Direction |

| 8 |

D6 |

Out |

n/a |

A Step |

| 9 |

D7 |

Out |

n/a |

A Direction |

| 10 |

S6 |

In |

Probe (Polarity=1) |

Probe (Polarity=1) |

| 11 |

/S7 |

In |

Probe (Polarity=0) |

Probe (Polarity=0) |

| 12 |

S5 |

In |

X, Y, Z Home (Polarity=1) |

A, X, Y, Z Home (Polarity=1) |

| 13 |

S4 |

In |

X, Y, Z Limit- (Polarity=1) |

Ground |

| 14 |

C1 |

Out |

n/a |

n/a |

| 15 |

S3 |

In |

X, Y, Z Limit+ (Polarity=1) |

Ground |

| 16 |

C2 |

Out |

n/a |

n/a |

| 17 |

/C3 |

Out |

n/a |

n/a |

| 18-25 |

Ground |

Ground |

Ground |

Ground |

Typically, systems that use L298's also use

the corresponding L297 [L297].

The L297 is a stepper motor controller chip

that provides a step and direction interface

to drive the L298 H-bridge. There are two

issues with the L297:

-

It is unclear whether the L297 is still

in full production. The supplies seem

to be getting more and more scarce.

-

Correspondingly, the cost of the L297

seems fairly high considering its

fairly modest functionality.

My preference is to use a less expensive

Microchip microcontroller that is dedicated

to do essentially the same task as the L297.

The

revision A uses a PIC16C505 and the

revision B uses a PIC16F628. (The

revision A design had a serious design

flaw.)

In order download the programs into the

microcontroller, a small PIC programmer is

placed in one corner of the board. (I hope

I have the board space!)

There are three kinds of wave tables that

make sense and these are listed below:

-

Wave Stepping

-

In wave stepping, only one coil is active

at a time. First coil A is tuned on,

then coil B, then coil A in the opposite

direction, then coil B in the opposite

direction and repeat. This mode consumes

the least amount of power and provides

the lowest amount of torque.

-

Full Stepping

-

In full stepping, the two coils are always

turned on. First A and B are forward,

then A in inverted, B is inverted, A

is pushed forward and repeat. The mode

consumes the most power and provides the

most torque (i.e. double the torque of

wave stepping.)

-

Half Stepping

-

In half stepping, the coils are turned

on in a sequence that provides twice as

many steps as the previous two modes.

With half stepping first one coil is

turned on, then two, then back to one

then back to two. It is basically

interleaved wave and full stepping.

All three tables are listed below:

| Wave Stepping |

| Phase |

CoilA+ |

CoilB+ |

CoilA- |

CoilB- |

| 0 |

1 |

0 |

0 |

0 |

| 1 |

0 |

1 |

0 |

0 |

| 2 |

0 |

0 |

1 |

0 |

| 3 |

0 |

0 |

0 |

1 |

| Full Stepping |

| Phase |

CoilA+ |

CoilB+ |

CoilA- |

CoilB- |

| 0 |

1 |

1 |

0 |

0 |

| 1 |

0 |

1 |

1 |

0 |

| 2 |

0 |

0 |

1 |

1 |

| 3 |

1 |

0 |

0 |

1 |

| Half Stepping |

| Phase |

CoilA+ |

CoilB+ |

CoilA- |

CoilB- |

| 0 |

1 |

0 |

0 |

0 |

| 1 |

1 |

1 |

0 |

0 |

| 2 |

0 |

1 |

0 |

0 |

| 3 |

0 |

1 |

1 |

0 |

| 4 |

0 |

0 |

1 |

0 |

| 5 |

0 |

0 |

1 |

1 |

| 6 |

0 |

0 |

0 |

1 |

| 7 |

1 |

0 |

0 |

1 |

It turns out that the microcontroller only

implements the half stepping wave table.

The other two tables can be `synthesized'

by simply using all even phase numbers

(Wave Table) or all odd phase numbers

(Full Stepping).

To simplify cabling, the motion board uses a

DB25 cable to connect from the controller to

the stepper motors, limit/home switches, and

linear/shaft encoders. Since DB25 cables

are primarily designed to support signal

transmission rather than power transmission,

a total of 8 wires are dedicated for each

coil (4 for each side.) Thus, a total of

16 wires are used for stepper motor power.

The remaining 9 wires (= 25 - 16) are used

for limit/home switch detection and

linear/shaft encoders. The pin-outs are

listed below:

| Pin |

| Number |

Name |

Direction |

| 1 |

Home |

In |

| 2 |

EncoderPhase1+ |

In |

| 3 |

CoilB+1 |

Power |

| 4 |

CoilB+2 |

Power |

| 5 |

CoilB-1 |

Power |

| 6 |

CoilB-2 |

Power |

| 7 |

Limit+ |

Current Loop |

| 8 |

CoilA+1 |

Power |

| 9 |

CoilA+2 |

Power |

| 10 |

CoilA-1 |

Power |

| 11 |

CoilA-2 |

Power |

| 12 |

+5V |

Power |

| 13 |

EncoderPhase2+ |

In |

| 14 |

Ground1 |

Ground |

| 15 |

EncoderPhase1- |

In |

| 16 |

CoilB+3 |

Power |

| 17 |

CoilB+4 |

Power |

| 18 |

CoilB-3 |

Power |

| 19 |

CoilB-4 |

Power |

| 20 |

Limit- |

Current Loop |

| 21 |

CoilA+3 |

Power |

| 22 |

CoilA+4 |

Power |

| 23 |

CoilA-3 |

Power |

| 24 |

CoilA-4 |

Power |

| 25 |

EncoderPhase2- |

In |

| 26 |

Ground2 |

Ground |

When it comes to limit switches there are two basic

strategies:

-

Advisory Strategy

-

The adviosory strategy is that a limit

switch event is forwarded to the software

that in turn responds by shutting the

whole machine down in a fairly graceful

fashion.

-

Depower Strategy

-

The depower strategy is that the moment

that a limit switch event occurs, power

is immediately removed from all drive

motors and spindle motors.

It should be noted that these two strategies are

not mutually exclusive. One set of limit switches

can be set up for an advisory strategy and another

set of limit switches can be set up for the depower

strategy. If the software does not get the machine

shut down when the advisory limit switch is triggered,

the depower limit switch can depower the whole

system.

EMC [EMC] implements the advisory

strategy for limit switches. I am real nervous about

relying exclusively on the advisory strategy because

it relies on some fairly complex software doing the

"right thing" in all circumstances. The next option

is the "let's support both". There are two problems

with supporting both -- first, the it takes up even

more cable conductors and board space, and second it

allows people to be sloppy about the depower switches,

since `after all they are really only there if the

first set does not work.' Ultimately, I decided that

I only wanted to support the immediate depower strategy.

This causes all limit switches to be hooked in series

with a current passing through all of them to a relay

that supplies drive and spindle motor power. If any

cable gets damaged, unplugged, or a limit switch is

triggered, the current throught the relay is cut off

and the whole system powers down. This is real simple

and real safe.

What this means for EMC is that the Limit- and

Limit+ are tied to ground. Thus, as far as

EMC is concerned, it will never get a limit

switch advisory signal.

The DB25 connector used to connect to each axis

has 4 wires set aside for transimitting standard

quadrature signals from linear/shaft encoders.

The two quadrature phases are sent using RS-422

levels to ensure that there is high noise rejectcion

due from the power pulses being sent down the

the same 25-wire cable.

The

Revision A and

Revision B versions of the

motion board are based on the EMC-style

advisory limit switches. The

Revision C is based on depower style of

limit switch.

The rest of the information about the motion

control board is kept in the

motion control directory.

{The Buffer Board is still in the early design phase.}

This section discusses the theory behind the buffer

board.

In the process of using CNC to manufacture a part,

a series of software and hardware tools are used to

transform the idea into physical reality. In theory,

a CAD system is used to design the part and a CAM

system is used to take the design and produce the

tool path that is used to manufacture the part.

The tool path is most typically represented as a file

in RS-274 format, which is also known as `G-codes'.

In the process of generating the toolpath, the CAM

system has to take into account the various

characteristics of the CNC equipment being used

and the properties of the material being machined.

Thus, the toolpath for an identical part being

machined on a CNC Bridgeport knee mill might be

quite a bit different from the toolpath on a CNC

Sherline table top mill. The additional power

available in the Bridgeport spindle, the increased

tool rigidity and increased X, Y, and Z axis power

allow the Bridgeport to take significantly deeper

and faster cuts over its smaller Sherline cousin.

None the less, the resulting part can be, for

all intents and purposes, identical.

Once the toolpath has been generated it is up to

CNC controller to take that G code and translate

it into a series of precisely timed and coordinated

moves on the CNC machine. The coordinate space

of G codes is in either English or Metric units

measured to fractions of inch or fractions of

a millimeter. The coordinate space of the CNC

machine is integral units where each unit is

typically something small like .00025 of an inch

or some such. The CNC controller is responsible

for converting from the G code coordinate space

to the machine coordinate space.

From an abstract point of view, the CNC controller

takes the G-Code and reduces it to a sequence of

timed events of the base form `at time t, move

to position (x, y, z)'. Combining the time time

into a four-tuple results in a sequence of

4-tuples (t, x, y, z). (This example is for a 3

axis machine, each additional axis would lengthen

the tuple appropriately.)

Historically the conversion of G codes to a sequence

of timed events has been done by a single dedicated

processor. However, it is possible separate the

generation of the timed event sequence from the

actual processing of the events on the CNC machine.

The timed event sequence can be generated on any

general purpose computer and the processing of the

timed events can be performed by specialized hardware

that can carefully emit the control signals at

exactly the right time. I call this specialized

hardware a buffer, since it is responsible for

storing up a bunch of motion commands and emitting

them at just the right rate.

The question arises, how big does the buffer need

to be? At one extreme the buffer can be large

enough to store all of the tuples before even

the first one is executed. At the other extreme,

the buffer can be of size zero and we are back

to the situation where the processor that is

computing the tuples is responsible for the timing

as well. In the middle, there is a buffer that

is large enough to ensure that the machine never

runs out of timed events (i.e. buffer under run) and

is not prohibitively expensive.

Before the question of how big the buffer is

can be answered, it is necessary to get a handle

on how much bandwidth is required between the

G-code to timed event converter and the buffer

board.

The timed event stream is amenable to a large

amount of compression. The first thing to note

is that the times are monotonically increasing.

The next thing to note is that when the machine

is moving from machine coordinate X1

to Xn it must traverse all intermediate

coordinates. Thus, delta encoding will result

in substantial bandwidth savings. Thus, the

sequence (123657, 23459, 5432, 98623),

(123663, 23460, 5432, 98623),

(123668, 23460, 5431, 98623) can be encoded

as an initial value of (123657, 23459, 5432, 98623)

followed by delta values of (6, 1, 0, 0) and

(5, 0, -1, 0). Note, that the first element

must always be positive and the remaining

elements must be -1, 0, or 1.

The rate at which these event tuples are

processed depends upon the maximum stepping

rate of the machine in question. If each

machine axis is capable of being ramped up to

100,000 steps per second, there are potentially

up to 3 × 100,000 event tuples per second

that need to be processed, since the steps

may not be occuring in sequence. If we set

aside 6 bits for the time delta, and 2 bits

for the each axis delta, that results in 10

bits per delta or 3 × 100,000 ×

10, or 3Mbps. While, this is not a small

number, it is nice to have an upper bound

on the required bandwidth.

Are there additional ways of compressing the

information? Certainly. The way that looks

the most promising to me is to break the

event stream up on a per axis basis. By noting

that the axis motor is limited by its maximum

acceleration and deceleration, it should be

possible to come up with a much more compact

representation of the axis event stream. For

example, if the motor is running at a constant

velocitiy, a simple run code compression can

be used. For run code compression, a sequence

of evently spaced events can be replaced by just

counting how many equally space events there are.

Similarly, when the motor speed is being changed,

a code that describes the amount of acceleration

(or deceleration) can compress a whole bunch of

motor events. Once the per axis event streams

have been computed, they can be mixed back together

to form a single unified stream.

One possible command stream might look as follows:

-

Axis Id (3-bits)

-

For a 3 or 4 axis machine, only 2-bits

are needed. For a full 6 axis machine

3 bits are needed.

-

Acceleration/Deceleration (5-bits)

-

This is a 5-bit signed two's complement

number. It is zero when the motor is

running at a constant speed. It is negative

to decelerate and positive to accelerate.

-

Event Count (8-bits)

-

The repeat count specifies how many event

counts are covered by this command.

The time is implied as the end of the previous

command for this axis. For example to deccelerate

the X axis from one step every 100 µS,

to one step every 200 µS, a command of

(0, -2, 100) would do the trick. To keep

the motor going for 1000 steps, 4 commands of

(0, 0, 250) would do the trick.

Yes, there are lots of details to work out.

However, I am quite hopeful that the bandwidth

required to keep a CNC machine happy can be

well under the 3Mbps mentioned above, preferably

under the 115Kbps that most asynchronous serial

lines need.

The next step is to get some more solid numbers.

In order to do this, my plan is to take the

Enhanced Machine Controller [EMC]

and modify it to produce an timed event stream.

After that, I intend to experiment a little to

figure out what kinds of compression work well

on the stream.

This is still pretty rough!

The buffer board has the following features:

-

The buffer board microcontroller is a

PIC16F877. This microcontroller has an

on board UART and 30+ I/O lines.

-

The PIC16F877 can be programmed in LVP mode.

The PIC505's can be programmed using an

on board PIC programmer.

-

Communication with the host processor occurs

either through an RS-232 connection or a

SimpliciNet connection.

-

The buffer board basically can independently

control 4 axes via the the standard parallel

port connector with standard EMC pinouts.

-

The limit and home signals for all axes are

individually accessable.

-

The current for each stepper motor can be

individually set, thereby providing the

ability to perform microstepping.

-

There is support for one linear or shaft

encoder with quadrature encoding on each

axis.

-

The spindle motor can be independently

controlled in both speed and direction.

The motor speed can be measured using

a tachometer signal.

-

The ability to read a few of the more

common SPC gage protocols is supported.

-

The buffer board has a second parallel port

output to support the second EMC parallel

port option. This second parallel port

provides additional controls above the

standard second EMC parallel port options:

-

A signal is provided for powering up and

down the stepper motor power supply.

-

A panic stop button is supported.

-

A sonic alarm is provided to get attention

that something is wrong.

-

The ability to control a tool changer.

This includes sensing tool home and the

the presense of tools.

-

The ability to control a power drawbar.

-

The ability to read an analog voltage for

EDM strength is provided. This can be used

to control EDM feedrate.

The following features did not make the cut:

-

Control Panel

-

A control panel allows the user to manually

control the CNC machine. This is best done

with a separate board that connects via

a SimpliciNet connection.

-

Power supply

-

The power supply should just be purchased

separately.

As usual, the shaft encoders use a dedicated PIC

to keep track of the position...

Before I get into the buffer board design, I would

like to point out that the individual revisions of

the buffer board are kept in a

buffer board revision directory..

{Remaining design issues go here.}

I have received useful feed back from `Ballendo'

and Doug Fortune about mistakes in this document

that I have attempted to correct. In addition,

I have found the CAD_CAM_EDM_DRO group at

Yahooo [E] to

be extremely informative. Other useful tidbits

of information have been mined from the

rec.crafts.metalworking newsgroup.

-

[CAD_CAM_EDM_DRO]

-

CAD_CAM_EDM_DRO group at

Yahoo. URL:

http://groups.yahoo.com/group/CAD_CAM_EDM_DRO/

-

[Camtronics]

-

Frames URL:

http://www.seanet.com/~dmauch/.

Non-Frames URL:

http://www.seanet.com/~dmauch/site_map.htm.

-

[EMC]

-

Enhanced Machine Controller

URL

http://www.isd.mel.nist.gov/projects/emc/ developed

by the

National Institute of Standards and Technology

The source code is available from

SourceForge at URL:

http://www.sourceforge.net/projects/emc/.

-

[CNCKits]

-

Frames URL:

http://cnckits.com/

Non-frames URL:

http://web.cuug.ab.ca/~fortuned/cnckits/

-

[Geckodrive]

-

URL:

http://www.geckodrive.com/.

-

[Glaister]

-

Lawrence Glaister's CNC pages. Main URL:

http://members.shaw.ca/cncstuff/

Bridge circuits URL:

http://members.shaw.ca/cncstuff/bridges.html.

EMC parallel port pinouts URL:

http://members.shaw.ca/cncstuff/emcio.html

-

[L297]

-

Stepper Motor Controllers by

ST.

-

[L298]

-

Dual Full Bridge Driver by

ST.

-

[LS7266R1]

-

The LS72661R1 is a 2 channel quadrature encoder

chip from

LSI Computer Systems Inc.

-

[Mauch1999]

-

Three-Axis Chopper, Step Motor Controller

for Computer Numerical Control (CNC)

Applications, Part 2 by Dan Mauch

June 1999 (pp. 6-8) issue of

Nuts and Volts magazine (Vol. 20, No. 6).

Part 2 of a 4 part series in the

May through

August issues.

-

[PIC16C505]

-

14-pin 8-bit CMOS Microcontroller by

MicroChip.

-

[RTLinux]

-

URL:

http://www.fsmlabs.com/.

-

[Rutex900]

-

Rutex

RT900 Motion Control IC.

-

[SimpliciNet]

-

SimpliciNet URL:

http://web.gramlich.net/projects/simplicinet/index.html.

-

[Wedemeyer1999]

-

Author: Hans Wedemeyer.

Bi-Polar Motor Driver.

-

URL:

http://hans-w.com/cnc.htm (about half

way down.) Image Only URL:

http://hans-w.com/9908-09A.gif.

This appendix contains some fairly free form

notes about CNC as I slowly start to figure

all this stuff out.

-

Mill Types

-

There appear to be two styles of

vertical mill -- a knee mill where

the spindle is kept rigid with

respect to the floor and the other

kind (name?) where the spindle is

moved veritcally in the Z axis.

Thus, the table for a knee mill

moves in the X, Y, and Z axes.

The other kind (name?) only moves

the table in the X and Y axises and

the spindle moves in the Z axis.

Knee mills seem to be bigger, so

they have more Z axis travel. The

larger Z axis travel translates into

fewer hassles with getting tools into

and out of the spindle.

-

Backlash

-

Leadscrew backlash is the slop in the

system as the table pushes agains one

side of the lead screw of the other.

An ideal milling system has no backlash.

Unfortunately, real milling systems

can have a great deal of backlash.

There are at least four ways (probably

many more) of dealing with backlash:

-

Ball Screws

-

A ball screw is magical device that

has ball bearings that push against

both sides of the lead screw at the

same time. By properly grinding and

hardening the lead screw and ball

screw races, wear is greatly reduced.

In addition to having essentially no

backlash, ball screws have very little

friction as well. The only drawback

is that they cost a small fortune.

They are not really an option for a

table top mill right now.

-

SuperNuts

-

I'm not sure I have the terminology

right here. Apparently there are

nuts that can be placed on a lead

screw to take out all of the backlash.

I suspect that they are somethting as

simple as two threaded nuts with a

spring between them. I need to find

out more here.

-

Pre Loading

-

Anyhow, the concept is to apply a

constant force to one side of the lead

screw. There are several ways of

accomplishing this task -- weight

and pullys, springs, etc.

A less clunky looking solution is to

mount another nut on the lead screw

and put a stiff spring between the two.

Any way it is done greatly increases

the friction and leadscrew wear. The

good news is that the hobbyist lead screws are pretty

cheap, so for hobbyist use, it is probably

OK to shorten their lifetime. Another

drawback is that the cutting tool can

temporarily overcome the side load force

and cause surface imperfections. The

big down side for side loading is the

need for larger motors to overcome the

increased friction.

-

Compensation

-

The more common strategy is to compensate

for backlash in software. This works

pretty well as long as the tool is

being pushed against one side of the

lead screw. Whenever there is an

inflection point in tool cutting path

the software quickly steps to the other

surface of the lead screw. But while

this is happening the cutting bit is

free to flop around a little. Again

this results in a surface imperfection.

-

Coupling Nut

-

A coupling nut is a longer threaded nut

made out of plastic material that is

at least 3 times longer than the diameter

of the leadscrew. It is inexpensive,

does not appear to add much wear and

does not appear to add much drag while

significantly reducing backlash.

As near as I can tell, most systems compensate

for backlash and deal with any resulting problems.

I suspect that there is some serious issue with

the side loading solution that I do not understand,

because I do not know of anybody that uses it.

There is an additional issue of uneven wear

on the lead screw. Since most travel occurs

in the middle of the lead screw, that is where

the most slop is introduced. For small machines,

the lead screw is cheap and should be replaced

when it gets unevently worn.

-

Encoders

-

An encoder is used to measures where the

X, Y, and Z axes are.

There are two kinds:

-

Linear encoder

-

The linear encoderss are attached to

the table proper and measure the exact

X, Y, and Z location in relation to

the spindle. The less expensive

encoders seem to be clocking in at

.001" to .00025". The linear system

can compensate for thermal expansion

and contraction in the table.

-

Shaft encoder

-

A shaft encoder sits on the lead

screw and measure thes amount of

lead screw rotation. A shaft encoder

can be be accurate up to 2048*4

counts per rotation. Given that

a lead screw might be 20 TPI (threads

per inch) this results in a theoretical

resolution of .0000061035". The big

disadvantage of shaft encoders is that

they only measure the lead screw

position, excluding any backlash.

Backlash will eat up the accuracy of

a shaft encoder.

-

SPC

-

SPC stands for Statistical Process Control.

The concept is to measure your parts and

notice when they are getting out of kilter

and replace the dull tool that is causing

the problem before they get too far out of

kilter. For the small hobbyist kind of guy

what this really means is that your

measurement tools have a digital output

that can be fed into a computer to be used.

The bad news is that there is not that much

standardization on the connectors, wires,

voltages, and protocol. Sigh, that means a

lot of custom adaptors.

There are two kinds of drive sytems:

-

Stepper Motor

-

A stepper motor is a motor without

a commutator that is controlled by

selectively turning coils on and

off. Stepper motors cost more per

lbf (pounds force) than DC motors.

-

Servo Motor

-

A servo motor is a standard DC motor

coupled with some feedback circuitry

to detect position errors an correct

them. DC motors cost less per lbf

(pounds force) than stepper motors.

There are pros and cons between using stepper

motors and servo motors to control everything.

Right now stepper motors seem to be holding the

low end of the market and servos are holding

the high end. For the same amount of torque,

stepper motors seem to be more expensive. For

a large machine, a large stepper motor will cost

a lot. Stepper motors can be run open loop.

Servo motors always have to have some sort of

feedback in the system. In theory, when a

stepper motor is not moving, it is being held

with a very large torque. When a servo motor

is not moving, its torque may be bouncing on

and off a little as the tool is pushed ever

slightly off its mark. On some servos systems

there is a certain roughness that results.

Other people claim this is really just an

improperly tuned servo system (and I tend to

agree.) The smaller mills seem to be standardizing

on NEMA 23 mounts for stepper motors.

Stepper motors coils are driven in cyclical

fashion. There are four ways to drive a stepper

motor:

-

4 steps per cycle, one coil active (wave)

-

This cycle is N, E, S, W and repeats.

-

8 steps per cycle (half stepping)

-

This cycle is N, NE, E, SE, W, SW, W, NW

and repeats. The NE, SE, SW, and NW

cylces have two coils simultaneously

active thereby doubling the torque

on those steps.

-

4 steps per cycle, two coils active (full stepping)

-

This cycle is NE, SE, SW, NW and repeats.

This cycle has twice the torque of the

first N, E, S, W cycle. Given that

stepper motors cost a lot for a given

torque, any technique that will double

the torque is pretty important.

-

Microstepping

-

With microstepping the current is varied

through the currently active two coils

to obtain an additional level of positioning

accuracy.

If too much current flows through a stepper motor

coil it will over heat and cause a motor failure.

There are four basic solutions.

-

Constant Voltage

-

The constant voltage system is the simplest

and slowest. If the stepper motor is rated

for N volts, no more than N volts is every

supplied to the coil. This is simple and

results in the lowest performance.

-

Series Resistor

-

A resistor can be placed in series with the

coil. A higher voltage is applied to the

coil. The series resistor is picked to

limit the current through the coil using

Ohms law (V = I * R). Essentially when

the coil is fully on, the voltage drop

across the resistor is same as the constant

voltage. When a coil is first activated,

the current can ramp up quickly because there

is no voltage drop across the resistor.

-

Chopper stablized

-

Chopper stablized is the next one up. A

higher voltage is supplied. The voltage

is turned on and off depending upon whether

the current is too high or not. The current

is sensed using a small current sensing

resistor near ground.

-

Variable voltage

-

I haven't seen this one done yet, but it

is pretty straight forward. The current

is measured and voltage is increased or

decreased appropriately. The voltage can

be supplied using a switching supply so

that it is not a power hog.

Right now the middle two seem to be the most used

solutions. Frankly, the variable voltage solution

should be given a try.

There are two kinds of stepper motors:

-

Bipolar

-

A bipolar stepper motor has two

coils. The each coil can be individually

activated. Call one coil the north

south coil and the other the East West

coil. This gives 8 possible activation

combinations - N, NE, E, SE, W, SW, W, and

NW. A bipolar stepper motor as a total

of four wires -- 2 wires for the north

south coil and the 2 wires for the east

west coil. Bipolar stepper motor coils

need to be driven with an H bridge to

be able to control which direction the

current flows through the coil.

-

Unipolar

-

A unipolar stepper motor is one that

that has two coils, but the each coil

has a center tap. Furthermore, the

windings on one side of the centertap

are clockwise and on the other side

they are counter clockwise. What this

means is that current from the centertap

to one side will activate the coil in

one direction (say north) and current

from the centertap to the othe size will

activate the coil in the opposite direction

(in this case south.) A unipolar stepper

motor can connect the centertap to a

positive voltage and use one transitor

on either end of the coil to control

energization direction. Thus, a unipolar

stepper motor does not need an H-bridge

to control current direction. In general,

a unipolar stepper motor of a given mass

has half the torque of a similar mass

bipolar stepper motor. This is because

only half the coil is active at a time.

Interestingly enough, it appears to be possible to

use unipolar stepping motors in a bipolar mode.

The only catch is you have to cut the current in

half because there are twice as many turns active

at a time. Very interesting.

There are at least three ways of connecting the

motor to the lead screws:

-

Direct drive

-

Direct drive hooks the motor shaft

directly to the lead screw shaft.

Done properly, there is no additional

backlash introduced.

-

Belt drive

-

The motor shaft is attached to the

lead screw shaft with a drive belt.

A reduction ratio can be added to

slow down a faster DC motor and

get correspondingly more torque.

There is an opportunity to add some

backlash into the system with belt

drive.

-

Gear Drive

-

A gear drive uses a gear train to

connect the motor shaft to the

lead screw shaft. One simple

strategy is to use a worm gear.

Like belt drives, backlash can

be added to the system.

Thermal expanstion and contraction rears its

ugly head in metalworking. As the temperature

changes, the metal part, the cutting tool,

and the machine tool expand and contract as

the temperatur changes. If the cutting tool

overheats, it will frequently be rendered

unusable. Whenever you are working on part

that need that level of accuracy, trying to

keep the temperatures constant starts to matter.

The big professional machining centers actually

will refrigerate the bearings, motors, etc. to

keep everything at a constant temperature. The

poor mans equivalent is to run everything in an

air conditioned shop; not as good, but not as

expensive either.

There seem to be at lest five kinds of cooling:

-

None

-

Basically, everything is ether run slow

so heat does not build up; or more

counter intuitively, things get done fast

so that the chips that are thrown out

carry most of the heat away.

-

Flood Cooling

-

A flood of cooling fluid is drenched over

the work piece. Everything is sprayed all

over the place. This is very effective

and quite messy. You need to have a drip

pan to collect the run off, a filter to

keep the chips out the pump, a pump to

pump it up again, etc. Lastly, the fluid

can mess up some the optical encoders out

there.

-

Mist Cooling

-

A fine mist of coolant is sprayed onto the

piece. Seems to work fine. There are

lots of complains about the mist getting

all over the shop and into people's lungs.

Yech.

-

Drip Cooling

-

A trickle of cooling fluid is dripped onto

the piece. There is much less splatter.

-

Hybrid Mist/Drip

-

There seems to be hybrid between mist and

drip whereby somebody has a fine mist wand

that is sprayed directly onto the part.

The lung irration complaints are way down.

-

Vortec Cooling

-

Vortec cooling uses swirling presurized

air and separates it into hot air and

cool air. The cool air is blown onto

the part. It is quite loud.

Lastly, the various liquid coolant systems can mess

up encoders real fast. Care needs to be taken to

keep the encoders sealed gains coolant. It tends

to be easier to seal a rotary encoder than a linear

encoder.

Where does that leave us? The first issue to

deal with is backlash control. For table top

systems, ball screws are out because they are

too expensive. That leaves conpensation vs.

preloading. With preloading friction is way up,

so the motors need to be correspondingly larger

to overcome the friction. However, this means

that the system can be run open loop with no

encoders. If encoders are added, they can be

the rotoary kind and sealed against any coolant.

If there is going to be no preloading, then

backlash compensation is a necessity. Open

loop backlash compensaton only works up to a

point. Linear DRO's will allow the system to

compensate out any backlash. They also

compensate out lead screw wear. The linear

DRO's need to be sealed agains any coolant.

For small hobby mills, both stepper and servo

systems will work. For now, it is probably better

to go with stepper motors in NEMA23 frames since

that seems to be the better supported solution.

It would be tempting at some point in the future

to try out an inexpensive gear drive motor directly

coupled to the shaft with an inexpensive shaft

DRO.

For stepper motors, bipolar motors with either

chopper drive or variable voltage seems to be

the way to go. Unipolars can be used in bipolar

mode.

Copyright (c) 2001-2002 by

Wayne C. Gramlich.

All rights reserved.