|

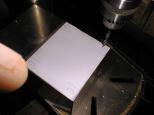

Using an ordinary piece of paper (taken from

the printer paper tray), the transformer is

positioned into one corner. Using a pencil,

the transformer feet are outlined along with

the slotted holes.

|

|

Remove the transformer and touch up the

traces so that they look acceptable.

|

|

Using ordinary scissors, the outpaper is

trimmed to size.

|

|

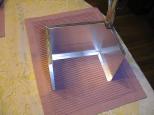

Using ordinary tape, the outline is taped to

the desired transformer location. I did not

worry about making a mirror image of the

template, since the transformer holes are

symetric.

|

|

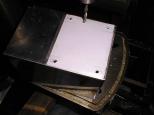

I temporarily put the two box pieces together

to make the box stiff. Using a sharp metal

awl, I dimpled four starter holes where I

wanted the holes to be drilled. I want the

drilled screws as close into the transformer

as possible, since lip inteference is going

to be a problem.

|

|

The hole is lined up on the drill press for

holes for #10-24 hardwarae.

|

|

The first hole is drilled

|

|

The remaining three holes are drilled.

|

|

The hardware for each hole consists of 1/2"

#10-24 round head screw, three #10 washers,

a #10 lock washer, and a #10-24 hex nut.

The picture only shows 2 washers per hole,

but when I finally put the transformer in,

I wound up using three #10 washers.

|

|

The paper template is no longer needed and it

is removed.

|

|

For each hole, I insert the 1/2" #10 round

head screw through the hole from the outside.

Next, on the inside, I put two #10 washers,

followed by the transformer leg, another #10

washer, a #10 lock washer and top it off with

a #10-24 hex nut. When all four screws are

mounted there is a little play in the transformer

left to move it around a little. After it is

positioned "just right", all four screws are

tightned down hard.

|

|

Afterwards the transformer is not going anywhere.

|

|

Next I put the other box piece on and notice

that the washers interfere with the box lips.

I knew that was coming.

|

|

Using a nibbling tool, I start removing metal

in all the places where the washers are hitting

the box lip.

|

|

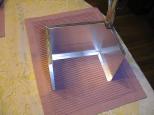

When I am done, there are three notches in

the box lip -- one in the corner, one in

the middle of the top edge, and one in the

bottom side.

|

|

When the box is put together, everything fits

just fine.

|