This is a portion of my CNC motion control board assembly documentation.

The purpose of the air filter is to prevent metal chips from accidentally getting into the controller and causing some sort of unintended short.

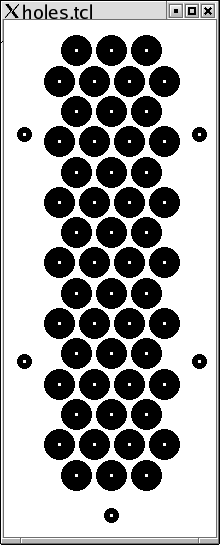

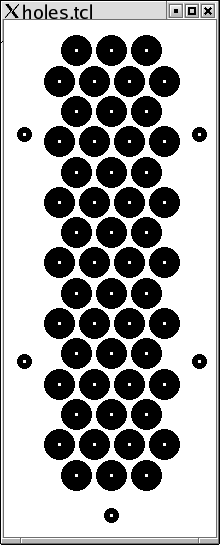

Normallly, I just use the component outlines, a ruler, and a pencil to generate a paper template for the part installation. This time around, I decided to let the computer do the drawing and I wrote a real quick tcl program to draw the template. The tcl program is shown below:

#!/usr/bin/wish

proc hole {x y diameter} {

#puts "x=$x y=$y diameter=$diameter"

set x_offset 20

set y_offset 0

set small 2

set radius [expr {$diameter / 2}]

set x1 [expr {$x_offset + $x - $radius}]

set x2 [expr {$x_offset + $x + $radius}]

set y1 [expr {$y_offset + $y - $radius}]

set y2 [expr {$y_offset + $y + $radius}]

.canvas create oval $x1 $y1 $x2 $y2 -fill black

set xx1 [expr {$x_offset + $x - $small}]

set xx2 [expr {$x_offset + $x + $small}]

set yy1 [expr {$y_offset + $y - $small}]

set yy2 [expr {$y_offset + $y + $small}]

.canvas create oval $xx1 $yy1 $xx2 $yy2 -fill white

}

#puts "Hello"

set rows 15

set columns 4

set horizontal_pitch 35

set diameter [expr {$horizontal_pitch - 5}]

set radius [expr {$diameter / 2}]

set vertical_pitch [expr {$horizontal_pitch * sqrt(3) / 2}]

set width [expr {$horizontal_pitch * ($columns + 2)}]

set height [expr {$vertical_pitch * ($rows + 2)}]

canvas .canvas -bg "white" -height $height -width $width

pack .canvas

for {set row 1} {$row <= $rows} {incr row} {

set y [expr {$row * $vertical_pitch}]

for {set column 1} {$column <= $columns} {incr column} {

set x [expr {$column * $horizontal_pitch}]

if {($row & 1) == 1} {

set x [expr {$x + $horizontal_pitch / 2}]

if {$column != $columns} {

hole $x $y $diameter

}

} else {

hole $x $y $diameter

}

}

}

set x1 0

set x2 [expr {$horizontal_pitch * ($columns + 1)}]

set x3 [expr {($x1 + $x2) / 2}]

set y1 [expr {$vertical_pitch * $rows / 4}]

set y2 [expr {$vertical_pitch * $rows * 3 / 4}]

set y3 [expr {$vertical_pitch * ($rows + 1) + $vertical_pitch / 3}]

set screw 15

hole $x1 $y1 $screw

hole $x1 $y2 $screw

hole $x2 $y1 $screw

hole $x2 $y2 $screw

hole $x3 $y3 $screw

This program is run and it draws the template I need.

Using a screen shot program (gimp) I generated the PNG

file below:

The big holes are air inlet holes and the small holes are mounting holes. Finally, I printed the template out and verified that it was the right size. I actually had to iterate several times to get the right pattern of air inlet holes that are about 1/4" in diameter.

The remaining steps are memorialized in pictures below: