|

The fan is placed on the corner of an ordinary

piece of paper.

|

|

Using a pencil, the outline of the fan is traced

on the paper.

|

|

Using ordinary scissors, the outline is cut out.

|

|

Using ordinary tape, the outline is taped to

the fan on the side that does not have any

struts holding the fan hub.

|

|

Using the side of an ordinary pencil lead,

the edges of the fan cavity and the mounting

holes are located. This is similar to placing

a piece of paper over a leaf and getting the

outline of the leaf. The result is kind of pretty.

|

|

Using an ordinary ruler, draw two lines that

intersect in the center.

|

|

Using an ordinary drill bit that fits snuggly

in the hole, drill out the four corner holes.

The resulting holes are not very clean.

|

|

Using an ordinary sharp utility knife, clean of

the tags of paper on the holes.

|

|

Using ordinary care, peel the paper template

off of the fan. There is no need to try and

remove the tape from the paper. Simply fold

the tape back over to back side of the paper.

|

|

Again, using ordinary tape, place the template

in the desired location of the fan on the box.

I accidentally let the fan get too close to the

transformer, so I had to carefully loosen the

transformer screws, and slide it over just little

so that the fan would fit, and then re-tighten

the screws. I taped all four sides down.

|

|

Using an ordinary utility knife, I carefully

cut the fan cavity outline out.

|

|

Using an ordinary sharp awl, I dimpled hole

starts for all four fan mounting holes.

|

|

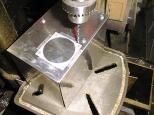

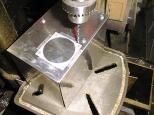

Using an ordinary drill press, I set up to

to drill the four mounting holes.

|

|

The first ordinary hole is drilled.

|

|

And the remaining three ordinary holes are

drilled.

|

|

Using a larger ordinary drill, a large

starter hole was drilled in the center.

|

|

An ordinary nibbler tool is inserted

into the starter hole and the fan cavity

hole is nibbled out. The resulting edge

is quite rough, but the fan will never

know.

|

|

Using a rotary file in the drill press,

the rough edges are smoothed out.

|

|

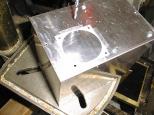

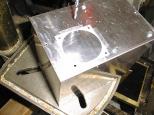

The resulting fan cavity hole is much

closer to circular.

|

|

This is a somewhat clearer picture of

the same hole in better lighting.

|

|

Using an ordinary round file, any left

over burrs are removed.

|

|

The fan is attached using 1-1/4 inch #6-32

round head screw, a lock washer, and 6-32

nut. The grill should help keep fingers

from touching the fan as it moves.

|

|

The screw goes through the grill first,

then the box, then the fan, then the

lock washer and finally the hex nut.

The result looks quite reasonable.

|