This is the Revision A version of the

PIC876Hub10 RoboBrick. The status of this project is

that it has been

replaced by the

Revision B version.

PIC876Hub10 Robobrick (Revision A)

This document is also available as a

PDF document.

The PIC876Hub10 RoboBrick is a master RoboBrick that

can control up to N slave RoboBricks. It uses a

PIC16F876 microcontroller from

MicroChip®. One of the hub

ports can be connected to a communications RoboBrick

to provide the ability to talk to the development

platform.

There is a three terminal connector, one for ground

and the other two for power. One power connector

is connected to a standard 3-terimal 5 volt regulator

to provide 5 volts to the slave RoboBricks. The

other power regulator is only sensed for voltage

level. The microcontroller has a built in analog

to digital converter that allows it to sense the

power level on both power terminals. When the power

goes below a preset level, the robot platform can

choose to enter a `hungry' behavior mode.

There is no programming specification for the PIC876Hub10

RoboBrick yet.

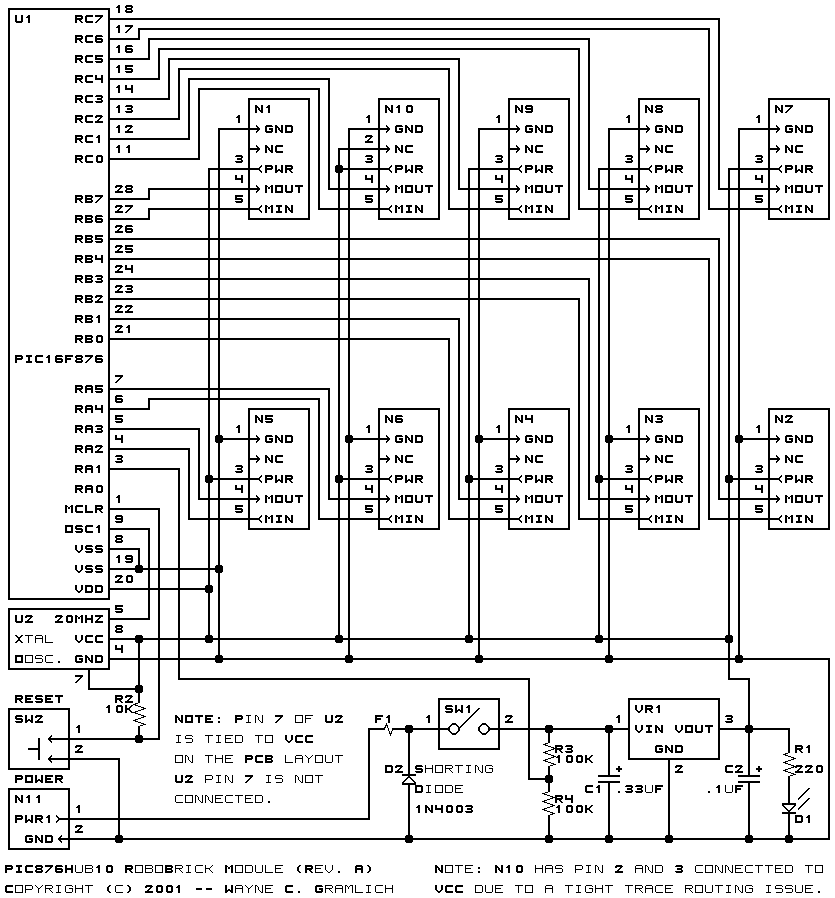

The hardware consists of a circuit schematic and

a printed circuit board.

The schematic for the PIC876Hub10 RoboBrick is shown below:

The parts list kept in a separate file --

pic876hub10.ptl.

The printed circuit board files are listed below:

-

pic876hub10_back.png

-

The solder side layer.

-

pic876hub10_front.png

-

The component side layer.

-

pic876hub10_artwork.png

-

The artwork layer.

-

pic876hub10.gbl

-

The RS-274X "Gerber" back (solder side) layer.

-

pic876hub10.gtl

-

The RS-274X "Gerber" top (component side) layer.

-

pic876hub10.gal

-

The RS-274X "Gerber" artwork layer.

-

pic876hub10.drl

-

The "Excellon" NC drill file.

-

pic876hub10.tol

-

The "Excellon" tool rack file.

There is no software for this RoboBrick yet.

The following fabrication issues came up:

-

The holes for N1-N10 (size 3) are too

large and should be made smaller (size 2).

-

Label the components in the upper right

corner better.

-

Think about making the holes for SW1 (size 4)

a bit larger (size 5).

-

The fuse is too long, make it .10 inches

or .15 inches shorter.

-

Think about rearranging the switch to be

a little higher up to get further away

from the heat sink on VR1.

-

Look around for an alternative processor

the has reprogrammable flash. They should

be starting to arrive on the scene.

-

Put a plus sign next to the appropriate

terminal of D1.

-

Put a plus sign next to the appropriate

terminal of D2.

-

Put a 1 next to the appropriate terminal

of U2.

-

Look for another more PCB friendly power

switch.

-

Look for a better push button.

-

Put a plus sign next to the appropriate

terminal of C1.

-

Try to find room for another terminal

on N1 and two resistors to build a second

battery voltage divider.

-

Think about adding a heart beat LED.

-

Move U2 down .05 inches so it does not

interfere with N10.

-

The crystal interfers with N10.

-

The reset button may not be needed.

Copyright (c) 2001-2002 by

Wayne C. Gramlich.

All rights reserved.